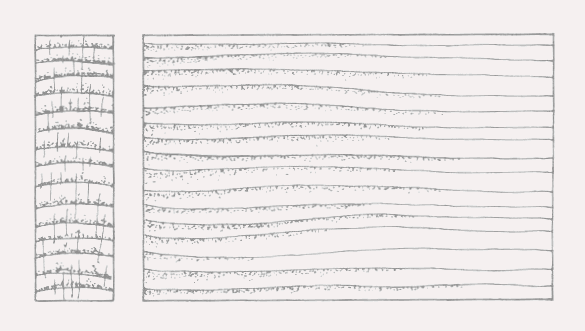

Rift Cut Veneer

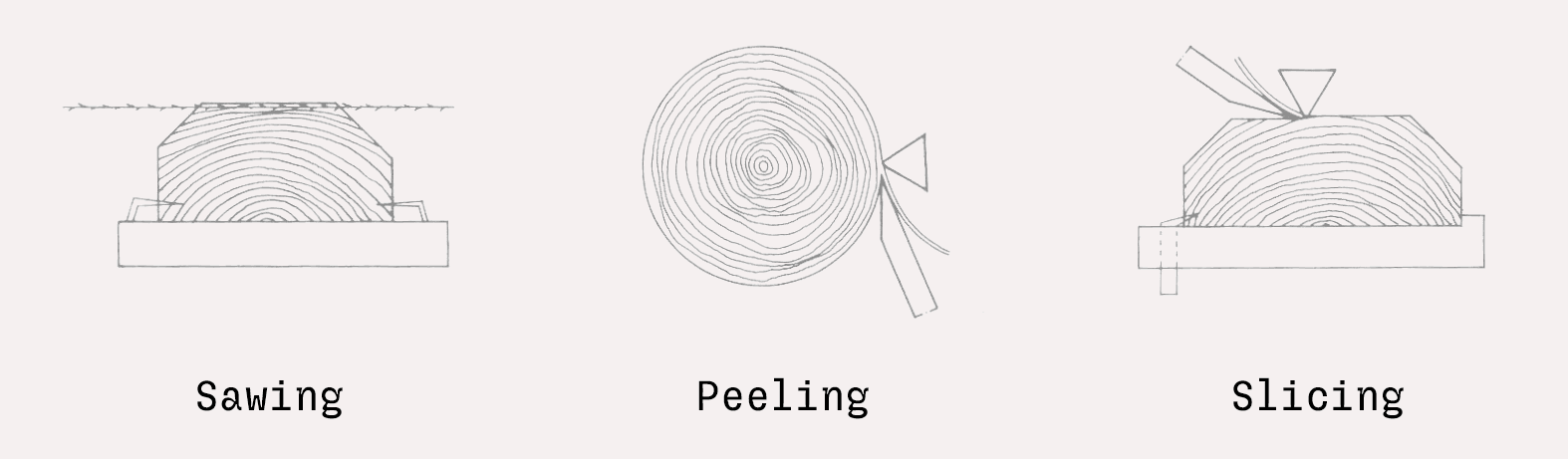

Rift cutting involves sawing wood at a right angle to the growth rings, aiming to minimize the appearance of medullary rays.

This technique produces straight grain lines with a consistent, uniform appearance.

Rift cutting is often used to create a modern or contemporary look in furniture and cabinetry.

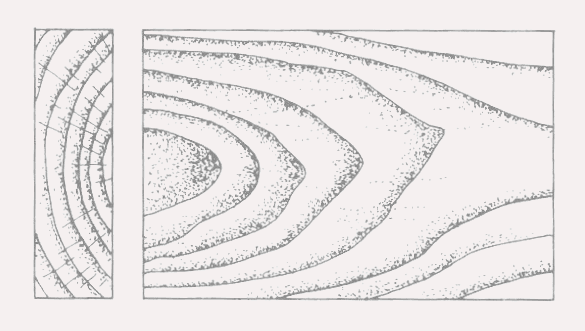

Flat Cut Veneer

Flat veneer refers to a method of slicing wood into thin sheets or veneers that range from strait grain to Catedral arch shaped grain

Flat veneer allows for greater flexibility and variety in wood species and grain patterns.

Catedral or arch shape grain patterns provide a variety of grain shapes

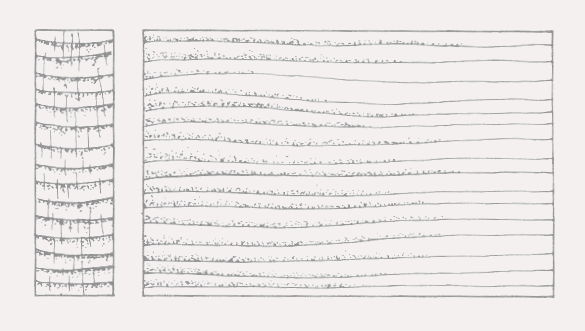

Quarter-sawn Veneer

Quarter sawing involves cutting a log into quarters and then sawing each quarter perpendicular to the growth rings.

This technique results in wood boards with a distinctive grain pattern called "ray fleck" or "tiger stripes."

Quarter sawn wood is known for its stability, resistance to warping, and durability.

Smooth

A smooth texture is achieved by sanding the wood until it is completely even and free from any visible marks or imperfections. It provides a sleek and polished look.

Wire-brushed

Wire brushing removes the softer parts of the wood, leaving behind a textured surface with distinctive grain patterns. It adds depth and character to the wood. Because of the thickness of our veneers, we can offer what no one can.

Scratched

This texture implies the marks left by the saw blade, resulting in a rustic and natural appearance. This texture is commonly used in flooring applications and often asked to match in the cabinetry.

Distressed

Distressing techniques involve creating intentional marks, dents, and scratches on the wood surface to mimic the appearance of age and wear. It adds a vintage or antique feel to the piece.

Weathered

Weathering techniques involve exposing the wood to natural elements, such as sun, rain, and wind, to simulate the effects of aging over time. It gives the wood a unique, aged look.

Reclaimed

Reclaimed wood often retains its original texture, showcasing nail holes, saw marks, and other character marks from its previous use. It adds a sense of history and sustainability to the woodwork.

We offer a unique way to treat our wood surfaces. We believe heavy stains can cloud the vision of the wood beneath. Toasting wood is a technique inspired by the traditional Japanese method known as Shou sugi ban, which involves charring the surface of wood to enhance its durability, appearance, and resistance to fire and decay. Toasting wood is a modern adaptation that offers a similar aesthetic effect while utilizing a different process.

During the toasting process, the wood is exposed to controlled heat or flame to achieve various levels of coloration and charring. The intensity and duration of the heat application can be adjusted to achieve different results. The goal is to lightly scorch the surface of the wood, highlighting its grain patterns, bringing out rich, darker tones, and creating a unique, weathered appearance.

Toasting wood offers several benefits beyond its visual appeal. The charring creates a layer of carbon that acts as a protective barrier, making the wood more resistant to insects, rot, and fire. The process also helps to seal the wood, reducing moisture absorption and increasing its dimensional stability.